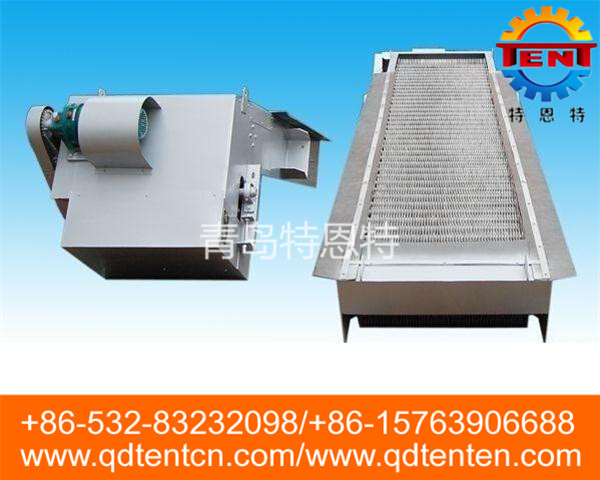

Mechanical grating decontamination machine

details

Machinery grille decontamination machine is a continuous automatic can intercept and remove various shapes of sundry in fluid sewage treatment of special equipment, can be widely used in urban sewage treatment, tap water industry, inlet of power plant, at the same time can also be used as a textile, food processing, paper making, leather and other industries in the process of wastewater treatment of the front-end screening equipment, is one of the most advanced solid-liquid screening equipment in our country, to fill the domestic blank.

Features of mechanical grating machine:

The equipment is one of the biggest advantages is the high degree of automation, high separation efficiency, low power consumption, no noise, corrosion resistant performance is good, in the case of unattended can guarantee the stability of continuous work, set up a overload safety device, the device fails, will produce sound and light alarm and automatically stop, and can avoid the equipment overload.

The device can adjust the running interval of the device at will according to the user's needs to realize periodic operation. It can be controlled automatically according to the level difference before and after grille. It also has manual control function to facilitate maintenance. The user can choose according to different work needs.

Due to the reasonable structure design of the equipment, when the equipment is working, it has a strong self-cleaning ability and will not be blocked, so the daily maintenance workload is very small.

Technical parameters and type selection:

1、Equipment and harrow teeth specifications�?/FONT>

The equipment is divided into HG300-3600 type according to the machine width. The machine is over 1800mm wide, then it is made and online. The gate gap is divided into 2mm, 3mm, 5mm, 10mm, 20mm, 30mm, 40mm, 50mm and other specifications. The gate gap is selected by the amount of water, lifting height, total amount of solid-liquid separation, the shape and particle size of the separated substances. The harrow teeth made of ABS engineering plastic, nylon and stainless steel can be selected according to the needs of users. The main frame is made of stainless steel and carbon steel.

2、Equipment length and specification: the standard groove depth of the equipment is 1500mm, which can be widened and lengthened at will according to the user's needs and actual usage.

二�?/FONT>Working principle

Mechanical grille machine is a kind of grille that can be continuously and automatically removed. It is composed of many identical harrow teeth machine parts staggered and parallel assembled into a set of closed harrow teeth chain. Driven by the motor and the reducer, a series of grooved wheels and chains are formed to form a continuous top-down circular movement, which can continuously remove the grille.When the chain of rake teeth runs to the upper part and back of the equipment, due to the guiding role of sprocket and bend rail, the parallel rake teeth can be dislocated, making the solid dirt fall into the slag groove by gravity and not clean off, such grille is easy to bring the dirt to the channel behind the grid.

When the wire rope traction drum mechanical grille works, the steel rope drive device puts the rope. The rake bucket descends along the guide rail from the highest position (at the end of the last cycle of skimming), and the skimmer plate decreases with the rake bucket under the action of self-weight. After skimming board reset, in open and close rake scraper device (electric putter) driven by steel rope traction among channels open and downward until arrival lower limit, after being insert grille clearance tine, steel rope drive line, further forced scraper scraper and hopper after closed completely along the guide rail upward, slag removal of grid until reach the skimming board, under the effect of relative motion between, the grid residue is left out, the guide plate slag fall into slag trough, to complete a working cycle.

三�?/FONT>Performance Advantages

The biggest advantage of mechanical grille machine is high automation degree, high separation efficiency, low power consumption, no noise and good corrosion resistance. It can work continuously and stably under unattended condition. It has set up overload safety protection device.

The device can adjust the running interval of the device at will according to the user's needs to realize periodic operation. It can be controlled automatically according to the level difference before and after grille. It also has manual control function to facilitate maintenance. The user can choose according to different work needs. Due to the reasonable structure design of the equipment, when the equipment is working, it has a strong self-cleaning ability and will not be blocked, so the daily maintenance workload is very small.

CONTACT US

+86-532-83232098

E-Mail:sales01@qdtent.com

addr:No. 1, Minan Road, Jiaoxi Industrial Park, Jiaozhou, Shandong, China